Innovating and growing in the textile world since 1969

We are a Spanish textile group founded in 1969 specialising in the broad sector of synthetic fibres

We have industrial plants in Spain, Brazil, Mexico and Poland

Aware of the need to protect the environment, we are involved in post-industrial and post-consumer recycling processes, as well as more environmentally friendly processes and technologies. This allows us to reduce energy and water consumption, and reduce the pollution produced by non-biodegradable waste.

The filament Spanish plants are located at Antex Group’s Headquarters in Anglès

Our plant in Brazil opened in 2001 is located in Fazenda do Rio Grande in the state of Paraná.

Our Mexican plant opened in 2010 in the state of Tlaxcala.

Antex Stilon. Production plant of polyamide and PBT filament yarns in Gorzów Wielkopolski (Poland)

Antex Fibres. Production plant of fibre in Andoain.

Our industrial processes include spinning, texturing by false twisting and by air, twisting, intermingling with elastomer, dyeing, sectional warping, Master Batch production and the development and the recycling of post-industrial and post-consumption waste.

Our plants’ geographical location combined with their proximity to principal international communication routes and our extensive production capacity allow us to respond to market demand with the utmost speed and efficiency.

Markets and sectors

ANTEX operates primarily in these markets and sectors.

Quality

All our production plants comply with strict regulations, needed to obtain all these quality certifications.

All our production plants comply with the strict regulations needed to obtain AENOR quality certifications. We have the IATF 16949 quality management system, which is an essential requirement in the automotive sector.

We are also certified in accordance with the UNE-ISO 9001 standard, which incorporates the design, development and production of yarns in the diverse industrial processes we offer.

The products we manufacture come with an OEKO-Tex® Standard 100 label warranty. Moreover, our commitment to the conservation and improvement of the natural environment has led to our implementing an environmental management system.

Aware of the growing importance of waste recycling and the need to incorporate recycled materials into the textile chain, and in order to assess the level at which our eco product lines have a reduced impact on the environment, we have carried out a life cycle analysis of our products (LCA).

In order to guarantee the traceability of our recycled material we offer a GRS certification, and a CCP certification for the recycling process. In addition, we have specific certifications covering different materials such as the SDS (Safety Data Sheet).

Our quality, safety and environmental policies are shared by all of our partners.

We uphold the United Nations (SDG) sustainable development objectives and work to ensure a better future for all.

R&D: One of our cornerstones

New trends require new solutions. Our R&D department is staffed by highly skilled specialists and guarantees both quality products and continuous innovative contributions to the textile market.

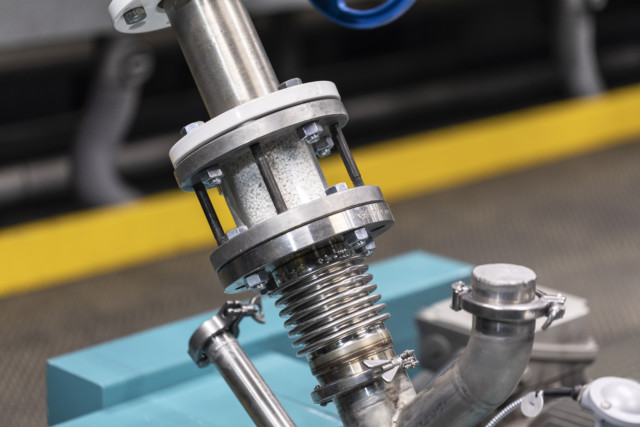

Thanks to our pilot plants our team of experts are able to dedicate the time and resources needed to investigate and develop new solutions independently from the daily production process. The studies and trials carried out in these plants are then tested in our laboratories

where the developed product is checked to make sure that it meets all initial specifications.

Technology at the service of quality

In order to ensure product continuity, all ANTEX processes have access to testing machinery of the same technology as that of our production machinery.

-

Spinning Flexible testing machines of 1, 2, 4 and 6 bobbins

-

False twist Texturing testing machines

-

Air texturing Individual positions

-

Dyeing Machines of 200 grams and up to 20 bobbins

-

Twisting 8 position machines

-

Master Batch Laboratory machines for small lots

-

High Elasticity Special internal process for coloured yarns with high bulk and stretch. Tailored bobbin constructions for perfect dyeing procedure and colour continuity

-

Fibres Synthetic fibre production adapted to the requirements of each application